Unlocking Efficiency with Microsoft Dynamics 365 Supply Chain Management (D365 SCM) is more than an aspiration it is a strategic imperative for organizations that seek to thrive in the ever-evolving, fast-paced global marketplace. At its core, unlocking efficiency means transforming how goods, information, and finances flow throughout the supply chain. With D365 SCM, enterprises are …

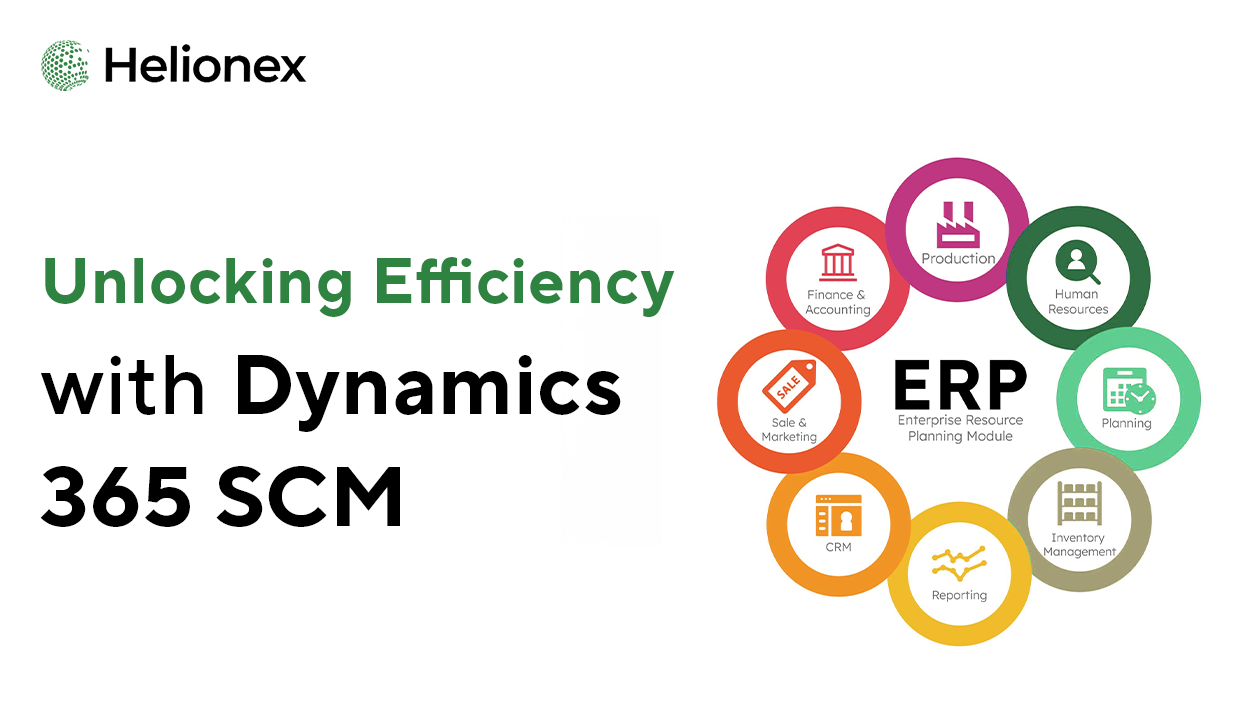

Unlocking Efficiency with Microsoft Dynamics 365 Supply Chain Management

Unlocking Efficiency with Microsoft Dynamics 365 Supply Chain Management (D365 SCM) is more than an aspiration it is a strategic imperative for organizations that seek to thrive in the ever-evolving, fast-paced global marketplace. At its core, unlocking efficiency means transforming how goods, information, and finances flow throughout the supply chain. With D365 SCM, enterprises are empowered to embrace digital transformation and proactively address today’s complexity through automation, seamless integration, and actionable insights.

Unlocking Efficiency with Microsoft Dynamics 365 Supply Chain Management: The Foundation

Implementing D365 SCM is not simply a software upgrade it is a commitment to operational excellence. Unlike traditional systems that focus solely on logistics, D365 SCM provides end-to-end supply chain visibility and intelligence, making it a true digital backbone. Every process from procurement through production and delivery is unified within a single, intelligent solution. This level of integration enables organizations to streamline financial management, eliminate data silos, reduce errors, and ultimately accelerate decision-making.

For many organizations, supply chain operations have become increasingly complex, involving international suppliers, fluctuating customer demands, and elevated expectations for speed and accuracy. Unlocking Efficiency with Microsoft Dynamics 365 Supply Chain Management addresses these challenges by automating workflows, optimizing processes, and offering predictive analytics that allow companies to stay ahead of disruption.

Imagine a scenario where sudden geopolitical shifts cause shipment delays. With D365 SCM, stakeholders receive instant notifications and can re-route deliveries based on real-time data. Resources are reallocated, communication is automated, and customers are promptly updated, protecting revenue and client trust all within a system that also helps streamline financial management at each step.

Table of Contents

- Introduction

- The D365 SCM Advantage

- Core Features for Supply Chain Transformation

- Inventory and Warehouse Management

- Procurement and Sourcing

- Production and Fulfillment

- Logistics and Transportation

- Asset Management

- How D365 SCM Streamlines Financial Management

- Industry-Specific Applications

- Real-World Success Stories

- Best Practices for Implementation

- Overcoming Common Challenges

- Conclusion

The D365 SCM Advantage

Unlocking Efficiency with Microsoft Dynamics 365 Supply Chain Management is rooted in the platform’s unique advantages over legacy systems and point solutions. One of its most powerful features is the ability to break down traditional operational silos. All supply chain functions procurement, inventory, production, distribution, and more are accessible in one ecosystem, fostering seamless communication and workflow automation.

Unlike disconnected ERPs that require cumbersome integrations, D365 SCM’s native connection with other Dynamics 365 applications, such as Finance and Commerce, enables organizations to streamline financial management by capturing real-time financial transactions directly from operational data. This visibility not only shortens closing cycles but supports compliance and strategic planning.

The scalability and flexibility of D365 SCM allow organizations to adapt quickly to changing business conditions, whether expanding into new markets, scaling manufacturing capacity, or accommodating remote and hybrid workforces. Built-in AI and machine learning capabilities help users forecast demand more accurately, optimize inventory holding, and mitigate risks before they impact the bottom line.

Core Features for Supply Chain Transformation

D365 SCM offers a robust suite of features that each play a critical role in unlocking efficiency and streamlining financial management throughout the supply chain. Let’s dive deeper into some of the most impactful modules.

Inventory and Warehouse Management

Efficient inventory management is the cornerstone of a responsive and cost-effective supply chain. With D365 SCM, inventory tracking and control become precise, error-free processes. The system enables organizations to:

- Maintain real-time visibility across multiple warehouses or retail locations globally

- Automate replenishment triggers based on actual sales and forecasting analytics

- Use barcode scanning and mobile devices to speed up stock counts, receiving, and picking

- Support multiple inventory methods (FIFO, LIFO, weighted average) for accurate valuation

- Integrate with financial ledgers to streamline financial management by linking every movement to an accounting impact

For example, an e-commerce company using D365 SCM no longer risks overstocking or running out of popular products. Adaptive replenishment rules anticipate sales surges such as during Black Friday and keep inventory at optimal levels. The system automatically records goods in and out, updating financial records and reducing manual reconciliation.

Procurement and Sourcing

Procurement teams are under pressure to control costs, mitigate supplier risks, and foster strong relationships. D365 SCM brings efficiency to the procurement process through:

- Seamless vendor collaboration portals for quotation requests and digital contracts

- Automated approval workflows aligned to company policies, which helps streamline financial management and maintain control over expenditures

- Real-time analytics on supplier performance, pricing trends, and delivery reliability

- Integration with inventory for just-in-time purchasing and reduced carrying costs

A manufacturer, for instance, can leverage D365 SCM to analyze historical supplier performance, flagging vendors with frequent delays. Approval workflows ensure that only authorized purchases proceed, giving finance teams confidence that budgets are adhered to a key step in unlocking efficiency and streamlining financial management.

Production and Fulfillment

Production planning is often a top challenge in manufacturing. D365 SCM helps businesses achieve peak performance by providing:

- Resource and production scheduling tools that adapt to real-time order changes and demand forecasts

- Bill of materials and route management for precise control of assembly lines and costs

- Quality management features to ensure finished goods meet customer expectations and regulatory requirements

- Integration with inventory to streamline financial management by tracking material consumption and scrap in real-time

Imagine a food processing plant that receives a sudden bulk order. D365 SCM dynamically reschedules machines, reallocates labor, and procures additional raw materials as needed. Costs are tracked instantly, supporting continuous improvement initiatives and detailed financial analysis.

Logistics and Transportation

Delivering the right product to the right place, at the right time and cost, is crucial for customer satisfaction. D365 SCM’s logistics capabilities enable businesses to:

- Optimize transportation routes based on cost, time, and carrier availability

- Monitor shipments in real time with GPS and IoT integrations

- Automate carrier selection and load planning to reduce empty miles

- Proactively update customers on delivery status via integrated communications

A retail chain using D365 SCM can quickly re-route shipments during weather events, avoiding costly delays and improving customer experience. Transportation costs are tracked and analyzed within the system, helping businesses streamline financial management and fine-tune logistics spending.

Asset Management

Maintaining equipment in top condition is vital to minimizing downtime and production costs. D365 SCM offers:

- Predictive maintenance using IoT sensors and analytics to anticipate failures

- Work order management for efficient scheduling of repairs and routine maintenance

- Cost tracking for spare parts, labor, and downtime events, which feed directly into financial metrics

- Integration with production, inventory, and finance so the total asset lifecycle is always visible

For example, a manufacturer can prevent unplanned outages by scheduling maintenance when sensors detect signs of wear. Financial impacts of downtime and repairs are instantly visible, supporting more effective asset investment strategies and cost control.

How D365 SCM Streamlines Financial Management

One of the most significant benefits of unlocking efficiency with Microsoft Dynamics 365 Supply Chain Management is the close alignment between operations and finance. Financial leaders gain powerful tools for:

- Automated journal entries based on transactional workflows (such as goods receipt or shipment)

- Real-time links between procurement spend, inventory value, production costs, and COGS

- Visibility into cash flow impacts of inventory holding, supplier payments, and receivables

- Streamlined financial management of complex multi-site, multi-currency operations

These capabilities make it easier to close periods, comply with regulatory reporting, and conduct deep profitability analysis. For example, when inventory is written down due to obsolescence, D365 SCM automatically adjusts the appropriate financial ledgers no manual intervention required.

Industry-Specific Applications

D365 SCM is trusted by organizations across industries, each with distinct challenges and requirements:

- Manufacturing: Supports mixed-mode production (discrete, process, project-based) and advanced scheduling for maximum output.

- Retail and E-commerce: Delivers omnichannel inventory visibility and accelerated fulfillment to meet evolving customer expectations.

- Distribution and Logistics: Empowers 3PLs and distributors to manage complex networks and value-added services at scale.

- Food & Beverage: Ensures food safety and compliance with robust traceability and quality management tools.

- Life Sciences and Healthcare: Facilitates product serialization, batch tracking, and compliance with strict industry regulations.

Across all these sectors, unlocking efficiency and streamlining financial management with Microsoft Dynamics 365 Supply Chain Management leads to cost savings, better margins, satisfied customers, and competitive advantage.

Real-World Success Stories

Consider a global electronics manufacturer that struggled with slow order fulfillment and excess inventory costs. After implementing D365 SCM, the business reported a 35% reduction in stockouts and improved order lead times by 28%. Integration with the financial module meant that procurement costs, manufacturing variances, and delivery expenses were automatically reflected in financial reports, simplifying audit compliance and streamlining financial management.

A national retailer using D365 SCM gained greater visibility across hundreds of locations, eliminating the guesswork from inventory planning and supplier negotiations. As a result, yearly losses from obsolete stock dropped dramatically, while real-time financial reporting provided clarity for leaders to confidently expand into new markets.

Best Practices for Implementation

Unlocking Efficiency with Microsoft Dynamics 365 Supply Chain Management requires a well-planned approach:

- Assess Current Processes: Map out where inefficiencies or data silos exist, especially at the intersections between supply chain and finance.

- Define Clear Objectives: Set measurable goals around inventory turns, on-time delivery, cost reductions, or other key metrics.

- Engage Stakeholders Early: Bring together cross-functional teams (procurement, production, logistics, finance) to ensure alignment.

- Start Small, Scale Fast: Begin with a pilot of core features, then expand as teams adapt and see value.

- Invest in Change Management: Continuous training and communication are vital for adoption.

- Measure and Refine: Use D365’s analytics tools to monitor KPIs, solicit feedback, and iterate for ongoing improvements.

Overcoming Common Challenges

While the benefits are substantial, transformation can present challenges such as resistance to change, data migration complexities, and the need for ongoing support. Tapping into expert guidance either from seasoned consulting partners or Microsoft specialists can accelerate the journey.

Some organizations have also leveraged native integration with Microsoft Power Platform for low-code process automation, enhancing supply chain workflows and enabling even further efficiency gains.

Conclusion

Unlocking Efficiency with Microsoft Dynamics 365 Supply Chain Management is not only about creating a smarter, more connected network it is about empowering every part of your business to collaborate and thrive. By unifying supply chain and financial processes, D365 SCM gives organizations the ability to anticipate market changes, reduce costs, accelerate order fulfillment, and deliver better customer experiences.

When you streamline financial management through automation, integrated workflows, and actionable intelligence, your company is poised for growth. Whether you are managing complex international operations or scaling up a local enterprise, Microsoft Dynamics 365 Supply Chain Management provides the tools and insights required for lasting success.

Harness the transformative power of D365 SCM to unlock efficiency at every level now and into the future.